Shenyang Shenjing Submersible Pump Co., Ltd.

Address: North Liguan West Peace Industrial Park, Yuhong District, Shenyang City

Contact number: Northeast sales phone: 024-25823018 89361125 89361461

Other areas: 024-25512305 25820388

Contact fax: 024-89361960

Email: shenjingbengye@163.com

Contact: Sales Department: 89361125, After-sales Service Department: 024-89361859

Website: www.ln-pump.com

First, WQ, QW type non-blocking mobile submersible sewage pump product introduction:

QW (WQ) type non-blocking submersible sewage pump is a new generation of pump products developed on the basis of introducing foreign advanced technology and combining the characteristics of domestic water pumps. It has remarkable energy saving effect, anti-winding, no clogging, automatic installation and Features such as automatic control. It has a unique effect in discharging solid particles and long-fiber waste.

This series of sewage pumps uses a unique impeller structure and a new mechanical seal to efficiently transport solids and long fibers. Compared with the conventional impeller, the impeller is in the form of a single flow channel or a double flow channel. It is similar to a curved pipe of the same cross-section. It has very good over-flow and is equipped with a reasonable volute to make the pump efficient. High and impeller dynamic and static balance test, so that the pump has no vibration during operation.

Second, WQ, QW type non-blocking mobile submersible sewage pump use conditions:

1. The medium temperature does not exceed 60 ° C; the medium weight is 1 ~ 1.3 kg / dm3.

2. The pump without the internal self-flow circulating cooling system, the motor part does not exceed 1/3 of the liquid level.

3, the use of cast iron material range PH5 ~ 9.

4, 1Cr18Ni9Ti stainless steel material is easy to be a corrosive medium.

5, the use of the environment altitude does not exceed 1000 meters, when it is exceeded, should be submitted at the time of order, in order to provide you with more reliable products.

Note: If the user has special temperature and media requirements, please indicate the details of the transport medium when ordering, so that the unit can provide more reliable products.

Third, WQ, QW type non-blocking mobile submersible sewage pump product features:

1. The unique single-piece or double-blade impeller structure greatly improves the dirt passing ability, and can effectively pass 5 times of the fiber diameter of the pump and the solid particles with a diameter of about 50% of the pump diameter.

2. The mechanical seal adopts a new type of hard and corrosion-resistant titanium tungsten carbide material, which can make the pump run safely for more than 8000 hours.

3. The overall structure is compact, small in size, small in noise, remarkable in energy saving effect, convenient in maintenance, no need to build a pump house, and can work in submerged water, greatly reducing the project cost.

4. The pump sealing oil chamber is provided with a high-precision anti-interference water leakage detecting sensor, and a thermal element is embedded in the stator winding to automatically protect the pump motor.

5. It can be equipped with automatic control cabinet according to the user's needs to automatically protect the pump from water leakage, leakage overload and over-temperature, which improves the safety and reliability of the product.

6. The float switch can automatically control the start and stop of the pump according to the required liquid level change, without special care, and is extremely convenient to use.

7.QW (WQ) series can be equipped with double-rail automatic coupling installation system according to users' needs. It brings more convenience to installation and maintenance, and people do not have to enter the sump for this purpose.

8. Can be used in the full lift, and ensure that the motor will not be overloaded.

9. There are two different installation methods, fixed automatic coupling installation system and mobile free installation system.

Fourth, WQ, QW type non-blocking mobile submersible sewage pump main use:

QW (WQ) series non-blocking submersible sewage pump is suitable for chemical, petroleum, pharmaceutical, mining, paper industry, cement plants, steel mills, power plants, coal processing industry, as well as urban sewage treatment plant drainage systems, municipal engineering, construction sites, etc. The industry transports particles of sewage, sewage, and is also used to pump clean water and corrosive media.

Five, product model:

产品品种 | 型号 | 流量 | 扬程 | 功率 | 电压 | 配管内径 | ||

WQ系列多级电机潜水排污电泵 | 4级 | 5.5KW3寸潜水排污泵-4级 | 80WQ80-13-5.5 | 80 | 13 | 5.5 | 380 | 80 |

5.5KW4寸潜水排污泵-4级 | 100WQ110-10-5.5 | 110 | 10 | 5.5 | 380 | 100 | ||

5.5KW6寸潜水排污泵-4级 | 150WQ150-7-5.5 | 150 | 7 | 5.5 | 380 | 150 | ||

7.5KW3寸潜水排污泵-4级 | 80WQ80-20-7.5 | 80 | 20 | 7.5 | 380 | 80 | ||

7.5KW4寸潜水排污泵-4级 | 100WQ100-15-7.5 | 100 | 15 | 7.5 | 380 | 100 | ||

7.5KW6寸潜水排污泵-4级 | 150WQ145-9-7.5 | 145 | 9 | 7.5 | 380 | 150 | ||

11KW4寸潜水排污泵-4级 | 100WQ100-25-11 | 100 | 25 | 11 | 380 | 100 | ||

11KW6寸潜水排污泵-4级 | 150WQ180-11-11 | 180 | 11 | 11 | 380 | 150 | ||

11KW8寸潜水排污泵-4级 | 200WQ300-7-11 | 300 | 7 | 11 | 380 | 200 | ||

11KW8寸潜水排污泵-4级 | 200WQ400-5-11 | 400 | 5 | 11 | 380 | 200 | ||

15KW4寸潜水排污泵-4级 | 100WQ100-30-15 | 100 | 30 | 15 | 380 | 100 | ||

15KW6寸潜水排污泵-4级 | 150WQ180-15-15 | 180 | 15 | 15 | 380 | 150 | ||

15KW8寸潜水排污泵-4级 | 200WQ250-11-15 | 250 | 11 | 15 | 380 | 200 | ||

18.5KW4寸潜水排污泵-4级 | 100WQ100-35-18.5 | 100 | 35 | 18.5 | 380 | 100 | ||

18.5KW6寸潜水排污泵-4级 | 150WQ150-26-18.5 | 150 | 26 | 18.5 | 380 | 150 | ||

18.5KW6寸潜水排污泵-4级 | 150WQ180-20-18.5 | 180 | 20 | 18.5 | 380 | 150 | ||

18.5KW6寸潜水排污泵-4级 | 150WQ200-15-18.5 | 200 | 15 | 18.5 | 380 | 150 | ||

18.5KW8寸潜水排污泵-4级 | 200WQ250-15-18.5 | 250 | 15 | 18.5 | 380 | 200 | ||

18.5KW8寸潜水排污泵-4级 | 200WQ350-10-18.5 | 350 | 10 | 18.5 | 380 | 200 | ||

18.5KW10寸潜水排污泵-4级 | 250WQ500-5-18.5 | 500 | 5 | 18.5 | 380 | 250 | ||

22KW4寸潜水排污泵-4级 | 100WQ100-40-22 | 100 | 40 | 22 | 380 | 100 | ||

22KW6寸潜水排污泵-4级 | 150WQ200-22-22 | 200 | 22 | 22 | 380 | 150 | ||

22KW8寸潜水排污泵-4级 | 200WQ250-18-22 | 250 | 18 | 22 | 380 | 200 | ||

22KW8寸潜水排污泵-4级 | 200WQ300-15-22 | 300 | 15 | 22 | 380 | 200 | ||

22KW8寸潜水排污泵-4级 | 200WQ400-10-22 | 400 | 10 | 22 | 380 | 200 | ||

22KW10寸潜水排污泵-4级 | 250WQ500-7-22 | 500 | 7 | 22 | 380 | 250 | ||

30KW6寸潜水排污泵-4级 | 150WQ180-30-30 | 180 | 30 | 30 | 380 | 150 | ||

30KW8寸潜水排污泵-4级 | 200WQ250-22-30 | 250 | 22 | 30 | 380 | 200 | ||

30KW10寸潜水排污泵-4级 | 250WQ600-9-30 | 600 | 9 | 30 | 380 | 250 | ||

30KW12寸潜水排污泵-4级 | 300WQ850-7-30 | 850 | 7 | 30 | 380 | 300 | ||

37KW6寸潜水排污泵-4级 | 150WQ180-37-37 | 180 | 37 | 37 | 380 | 150 | ||

37KW8寸潜水排污泵-4级 | 200WQ250-25-37 | 250 | 25 | 37 | 380 | 200 | ||

37KW10寸潜水排污泵-4级 | 250WQ700-11-37 | 700 | 11 | 37 | 380 | 250 | ||

37KW10寸潜水排污泵-4级 | 250WQ600-12-37 | 600 | 12 | 37 | 380 | 250 | ||

37KW12寸潜水排污泵-4级 | 300WQ800-10-37 | 800 | 10 | 37 | 380 | 300 | ||

45KW6寸潜水排污泵-4级 | 150WQ180-45-45 | 180 | 45 | 45 | 380 | 150 | ||

45KW8寸潜水排污泵-4级 | 200WQ400-20-45 | 400 | 20 | 45 | 380 | 200 | ||

45KW10寸潜水排污泵-4级 | 250WQ600-15-45 | 600 | 15 | 45 | 380 | 250 | ||

45KW12寸潜水排污泵-4级 | 300WQ500-15-45 | 500 | 15 | 45 | 380 | 300 | ||

45KW12寸潜水排污泵-4级 | 300WQ800-12-45 | 800 | 12 | 45 | 380 | 300 | ||

55KW6寸潜水排污泵-4级 | 150WQ200-50-55 | 200 | 50 | 55 | 380 | 150 | ||

55KW8寸潜水排污泵-4级 | 200WQ300-40-55 | 300 | 40 | 55 | 380 | 200 | ||

55KW8寸潜水排污泵-4级 | 200WQ400-30-55 | 400 | 30 | 55 | 380 | 200 | ||

55KW10寸潜水排污泵-4级 | 250WQ600-20-55 | 600 | 20 | 55 | 380 | 250 | ||

55KW12寸潜水排污泵-4级 | 300WQ800-15-55 | 800 | 15 | 55 | 380 | 300 | ||

Sixth, WQ, QW type non-blocking mobile submersible sewage pump Note:

1. Before using the pump, carefully check whether the cable is damaged, whether the fastener is loose or falling off, and whether the pump is deformed or damaged during transportation, storage and installation.

2. Measure the same and relative ground insulation resistance of the electric pump motor with a 500V megger. The value should be no less than 2 megohms. Otherwise, the stator winding of the motor should be dried. The temperature of the drying process must not exceed 120 °C.

3. The pumps are available in both fixed and mobile versions. When using the fixed automatic installation, the chain should be inserted into the two eyebolts or the lifting plate in the lifting and lowering of the two cables (the water outlet of the pump should be parallel to the pump outlet). Slide down evenly and slowly along the rail until it is automatically coupled into place. When using mobile installation, first set the hose, and use the chain to penetrate the two lifting rings to lift the electric pump up and down. Be careful not to use the cable as a rope to avoid danger.

4. The direction of rotation after the pump is turned on is counterclockwise from the water inlet. If the pump is reversed, simply adjust any two wires in the cable to the wiring position.

5. The ground wire of the casing of the electric pump must be strictly in accordance with the relevant regulations. In order to ensure personal safety during use, it is strictly forbidden to install people to work or move in the vicinity when the electric pump is running, in case accident occurs due to electric leakage of the electric pump. accident.

6. The electric pump must be equipped with a fully automatic water pump control cabinet without special circumstances. Do not connect the power grid directly or use the knife switch to turn on the power supply to ensure the normal operation of the electric pump.

7. Do not operate the pump for a long period of time with low lift (usually the head should not be lower than 60% of the rated head). It is best to control it within the recommended head range to prevent the motor from burning out the motor due to overload.

8. The pump without self-circulating cooling device is forbidden to be exposed to the water surface for a long time to prevent the electric pump from being overheated and damaged.

Seven, WQ, QW type non-blocking mobile submersible sewage pump maintenance and maintenance:

1. The electric pump should be managed and used by a special person. The well should regularly check whether the insulation resistance between the electric pump winding and the casing is normal.

2. After each use, especially for thicker and more viscous slurry, the electric pump should be put into clean water for a few minutes to prevent deposits in the pump and ensure the cleaning of the pump.

3. If the electric pump is not used for a long time, the electric pump should be taken out of the water. Do not soak it in the water for a long time to reduce the chance of moisture in the stator winding of the motor and increase the service life of the electric pump.

4. After the electric pump is disassembled and repaired, the casing components must be inspected by a 0.2MPa airtight test to ensure reliable motor sealing.

5, the sealing ring between the impeller and the pump body has a sealing function, such as seal damage will directly affect the performance of the pump, if necessary, should be replaced.

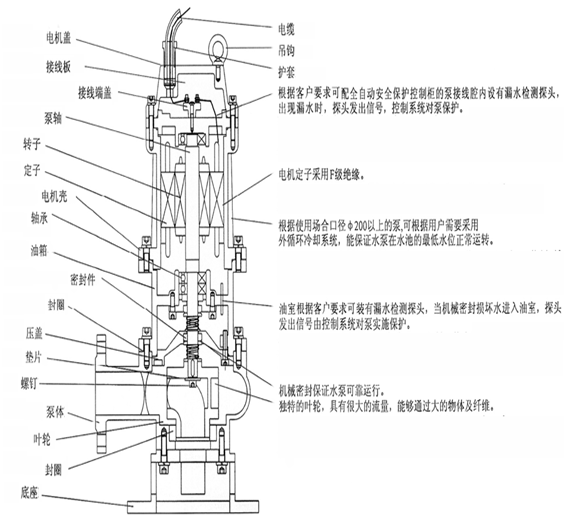

Eight, WQ, QW type non-blocking mobile submersible sewage pump structure diagram:

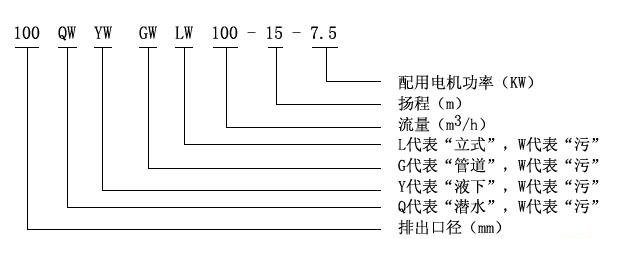

Nine, WQ, QW type non-blocking mobile submersible sewage pump model definition: