Shenyang Shenjing Submersible Pump Co., Ltd.

Address: North Liguan West Peace Industrial Park, Yuhong District, Shenyang City

Contact number: Northeast sales phone: 024-25823018 89361125 89361461

Other areas: 024-25512305 25820388

Contact fax: 024-89361960

Email: shenjingbengye@163.com

Contact: Sales Department: 89361125, After-sales Service Department: 024-89361859

Website: www.ln-pump.com

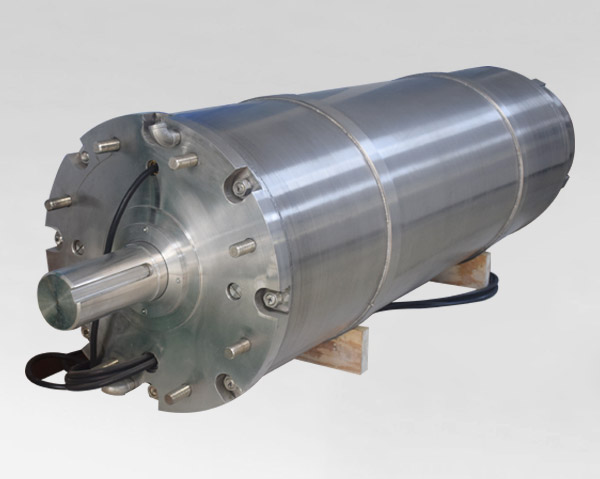

Our company specializes in the explosion-proof submerged oil pump, adopts the electric drive principle, grades the crude oil and special media such as LNG and LPG, and adopts special materials such as duplex stainless steel to improve the quality of the product and improve the service life of the product.

Model classification: divided into DY multi-stage centrifugal oil pump, AY centrifugal oil pump, explosion-proof cleft submersible pump.

Application fields: Submersible pumps can be roughly divided into four types according to their main purposes: submersible oil pumps for gas stations; submersible oil pumps for oil depots (refueling vessels), submersible oil pumps for tank cranes; oil and oil submersible pumps for oil wells; underground The cavern enhances the crude oil electric drive submersible pump.

Model list: flow 20~3000m3/h, head: 15~300m.

Use requirements: a. For petrochemical pumps that transport flammable, explosive, toxic or valuable media, shaft seals are required to be reliable or leak-free pumps, such as shielded pumps, magnetically driven pumps, pneumatic diaphragm pumps, etc.

b. For petrochemical pumps that transport corrosive media, it is required that the flow-through components be made of corrosion-resistant materials.

c. For petrochemical pumps that transport solid particle media, the flow-through components are required to be wear-resistant. If necessary, the shaft seal should be flushed with a clean liquid.

Installation requirements: a. For petrochemical pumps installed in the presence of corrosive gases, measures to prevent atmospheric corrosion are required.

b. For petrochemical pumps installed in outdoor ambient temperature below 20 °C, it is required to consider the cold and brittle phenomenon of the pump and adopt low temperature resistance.

material.

c. For petrochemical pumps installed in explosive areas, explosion-proof motors should be used according to the level of the explosion area.

d. For plants that require annual overhaul, the continuous operating cycle of the pump should generally not be less than 8000h. In order to meet the requirements of a three-year major overhaul, API 610 (10th Edition) stipulates that the continuous operation cycle of pumps for the petroleum, petrochemical and natural gas industries is at least 3 years.

e. The design life of petrochemical pumps is generally at least 10 years. API 610 (10th Edition) stipulates that centrifugal pumps for the petroleum, petrochemical and natural gas industries have a design life of at least 20 years.

f. The design, manufacture and inspection of petrochemical pumps shall comply with the relevant standards and specifications.

g. The performance of the pump within the range of supply voltage and frequency variation should be guaranteed. The variation range of power supply voltage and frequency in China is: voltage 380V±10%, 6000V±10%; frequency 50Hz±1Hz.